Top SMT Circuit Board & PCB Assembly Manufacturing: Surface Mount Technology and Precision PCB Solutions

Top SMT Circuit Board & PCB Assembly Manufacturing: Surface Mount Technology and Precision PCB Solutions

Blog Article

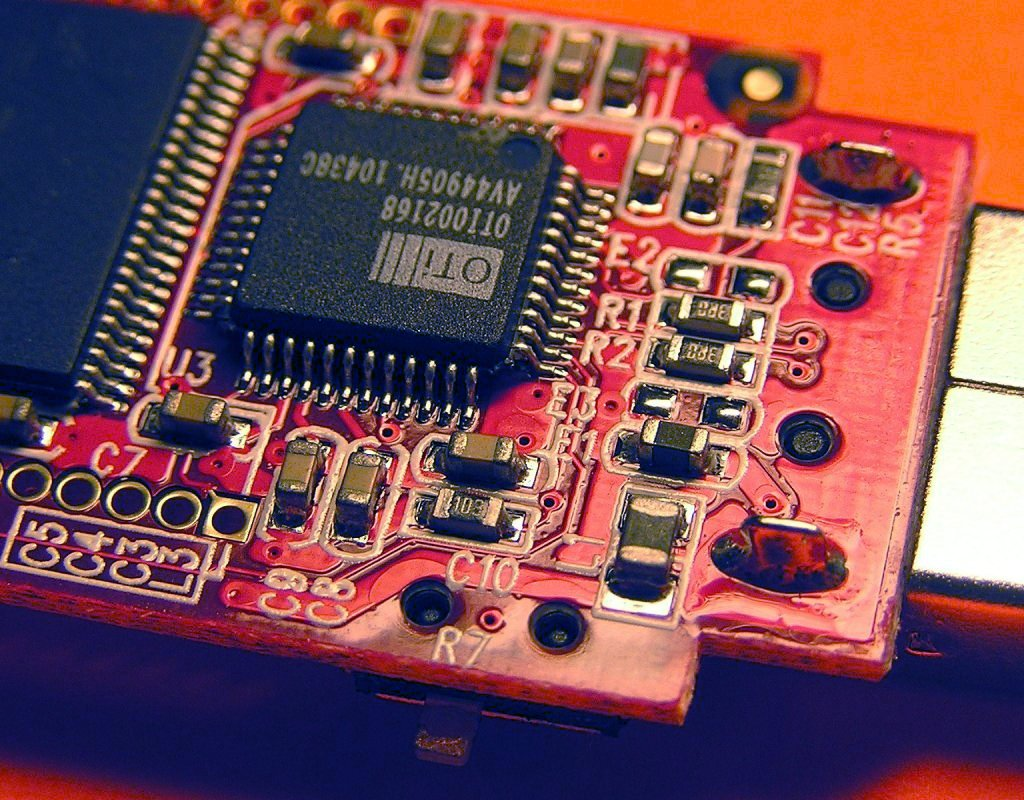

Printed circuit boards, or PCBs, are integral elements in nearly every electronic device used in the modern, rapidly changing world of electronics. These sheets act as the foundational system for electronic circuits, empowering the physical mounting and electrical association of different components. Among the different PCB innovations, Surface Mount Technology (SMT) has ended up a prevailing strategy in gadgets fabricating due to its productivity, unwavering quality, and miniaturization capabilities. This article will investigate SMT Circuit Boards, Surface Mount PCB, SMT PCB Sheets, and PCB Assembly Fabricating, advertising a comprehensive direct for understanding the different components of this pivotal technology.

What is an SMT Circuit Board?

Surface Mount Technology (SMT) Circuit Boards are a sort of PCB where electronic components are mounted specifically onto the surface of the board, or maybe than being fastened into gaps (as in conventional Through-Hole Technology). SMT revolutionized PCB fabricating by permitting littler and more effective plans, essentially decreasing the estimate and weight of electronic products.

SMT Circuit Sheets have components, known as Surface Mount Devices (SMDs), patched specifically to the board’s surface without requiring long leads. These components can be put on both sides of the board, assist improving plan adaptability and functionality.

Key Characteristics of SMT Circuit Boards:

• Compact Measure: SMT permits for more components to be stuffed into a littler space, driving to lighter and more compact devices.

• Automated Gathering: The computerization of SMT forms guarantees speedier and more effective generation of PCBs.

• Cost-Effective: SMT diminishes the require for penetrating gaps, driving to lower fabricating costs.

Surface Mount PCB: A More profound Dive

Surface Mount PCBs are the physical sheets that bolster the Assembly of surface-mount components. They comprise of layers of conductive fabric (as a rule copper) and protection layers that offer assistance course electrical signals between components.

Structure of Surface Mount PCBs:

Surface Mount PCBs comprise of numerous layers, including:

1. Substrate: This is the base fabric, regularly made from fiberglass or other protection fabric, that gives the PCB its structure.

2. Copper Layer: Conductive copper follows are included to the substrate, permitting power to stream between components.

3. Solder Cover: This layer covers the copper follows to secure them from coincidental short-circuiting or harm. It too gives the characteristic green color of PCBs.

4. Silkscreen: Utilized to include names and markings for simple distinguishing proof of components and connections.

5. Solder Glue: Patch glue is connected to the PCB where components will be mounted, guaranteeing a solid electrical association when heated.

Advantages of Surface Mount PCBs:

• Higher Component Thickness: SMT empowers littler and lighter plans with higher component thickness than through-hole PCBs.

• Reliability: SMT patch joints are by and large more dependable due to the littler estimate and diminished mechanical stretch on components.

• Lower Fabricating Costs: The decreased require for gaps and the capacity to computerize the gathering prepare make SMT PCBs more cost-effective.

• Better Electrical Execution: Surface mount components ordinarily have shorter leads, diminishing inductance and moving forward execution in high-frequency applications.

The SMT PCB Board: Key Components and Applications

The SMT PCB board speaks to a particular sort of PCB utilizing surface mount innovation. Whereas comparable to other PCB sorts, SMT Boards offer a set of unmistakable focal points due to their plan and gathering methods.

Key Components on SMT PCB Boards:

• Resistors: Fundamental components that constrain the sum of current streaming through a circuit.

• Capacitors: Store and discharge electrical vitality, smoothing out voltage variances in the circuit.

• Integrated Circuits (ICs): Microchips that serve as the brains of electronic gadgets, performing complex handling and control functions.

• Diodes: Permit current to stream in one course whereas blocking it in the inverse heading, frequently utilized for correction in control supplies.

• Transistors: Act as switches or speakers in electronic circuits.

• Inductors: Store vitality in a attractive field, ordinarily utilized in control supplies and RF applications.

Applications of SMT PCB Boards:

SMT PCB Board are utilized in a wide run of electronic gadgets over different businesses. Key applications include:

1. Consumer Hardware: Smartphone's, tablets, tablets, and other versatile gadgets depend on SMT PCB sheets for their compact and productive designs.

2. Automotive Industry: Present day cars contain various SMT PCBs that control everything from motor administration to infotainment systems.

3. Medical Gadgets: Pacemakers, symptomatic gear, and checking gadgets utilize SMT PCBs for their unwavering quality and miniaturization.

4. Aerospace and Defense: SMT PCBs are utilized in aeronautics, satellites, and military communication frameworks due to their strength and precision.

5. Telecommunications: Organize gear, such as switches and switches, employments SMT PCBs for high-performance information processing.

PCB Assembly Manufacturing: From Design to Finished Product

PCB Assembly fabricating includes a few stages, from the starting plan stage to the last testing of the gathered board. This prepare is profoundly computerized, particularly in SMT fabricating, to guarantee tall exactness and productivity. Here is an outline of the ordinary steps included in PCB gathering manufacturing.

1. PCB Design and Layout

Before any physical fabricating starts, the PCB must be carefully planned utilizing Computer-Aided Design (CAD) computer program. This handle includes laying out the electrical pathways (follows), component arrangement, and other basic highlights such as control and ground planes.

In the SMT handle, architects must consider particular variables such as:

• Component estimate and dispersing: Guaranteeing there’s sufficient room for robotized pick-and-place machines to introduce SMDs accurately.

• Thermal administration: Tending to warm scattering issues that emerge from compact designs.

• Signal keenness: Minimizing electromagnetic interference (EMI) and guaranteeing solid flag transmission.

2. Solder Paste Application

After the PCB is manufactured, a stencil is utilized to apply patch glue onto the copper cushions where the SMDs will be mounted. Patch glue comprises of little metal patch particles suspended in flux, which makes a difference guarantee a great association between the components and the board.

3. Pick-and-Place Machine

The pick-and-place machine is an fundamental portion of the SMT Assembly prepare. It employments exact automated arms to choose up SMDs and put them on the PCB in the adjust position, based on the plan file.

The pick-and-place prepare involves:

• Component recognizable proof: Machines utilize vision frameworks to distinguish and confirm the rectify components.

• Alignment: Components must be precisely adjusted with the patch paste-covered cushions on the PCB.

• Placement speed: High-speed pick-and-place machines can introduce thousands of components per hour.

4. Reflow Soldering

Once the components are in put, the PCB is passed through a reflow broiler. This broiler warms the board, causing the patch glue to liquefy and shape a strong patch joint between the components and the PCB. The board at that point cools down, cementing the connections.

Reflow fastening is a basic step in SMT PCB Assembly, as disgraceful warming can cause issues such as:

• Cold patch joints: Frail associations due click here to deficiently heating.

• Bridging: Overabundance patch making undesirable associations between adjoining components.

• Component move: Components moving out of put amid the reflow process.

5. Assessment and Testing

After the reflow patching handle, the PCB is altogether reviewed Surface Mount PCB for any abandons or issues. Automated optical inspection (AOI) frameworks are commonly utilized to confirm component arrangement and patch joint quality. X-ray assessment may too be utilized for more complex sheets with covered up patch joints.

Testing strategies include:

• In-circuit testing (ICT): Guarantees that each component is working correctly.

• Functional testing: Confirms that the completely gathered PCB performs its planning function.

• Burn-in testing: Subjecting the PCB to raised temperatures and voltages to distinguish early failures.

6. Last Assembly and Packaging

Once the PCB has passed review and testing, it may experience assist Assembly steps, such as including connectors, heat sinks, or other components. The completed sheets are at that point bundled and transported to clients for integration into last products.

Challenges in SMT PCB Assembly Manufacturing

While SMT PCB assembly offers various focal points, it too presents a few challenges that producers must address to guarantee high-quality production.

1. Component Miniaturization

As components proceed to recoil in measure, producers confront challenges related to component situation exactness and patching accuracy. Robotized machines must be able of dealing with progressively littler components without compromising performance.

2. Warm Management

With more components stuffed into littler spaces, warm dissemination gets to be a basic issue. Producers must plan PCBs with compelling warm administration procedures, such as warm sinks or warm vias, to avoid overheating and guarantee long-term reliability.

3. Flag Integrity

As PCBs gotten to be more thickly populated, the hazard of electromagnetic interference (EMI) increments. Producers must carefully plan PCBs to minimize flag clamor and guarantee legitimate flag judgment, particularly in high-frequency applications.

4. Lead-Free Soldering

In reaction to natural directions such as the Restriction of Hazardous Substances (RoHS) order, numerous producers have transitioned to lead-free patching. In any case, lead-free patches have distinctive properties than conventional leaded fastens, driving to challenges such as higher reflow temperatures and expanded helplessness to absconds like delicate patch joints.

Future Patterns in SMT PCB Assembly Manufacturing

As innovation proceeds to progress, a few patterns are forming the future of SMT PCB assembly fabricating. These patterns include:

1. Progressed Materials

New materials such as adaptable and stretchable PCBs are developing, empowering the improvement of inventive items like wearable hardware and foldable gadgets. These materials require specialized gathering methods, pushing the boundaries of conventional SMT manufacturing.

2. Miniaturization and Integration

The drift toward littler, more coordinates electronic gadgets is driving request for littler components and more compact PCB plans. Progressed bundling innovations, such as system-in-package (Taste) and chip-on-board (COB), are getting to be progressively critical in assembly these demands.

3. Keen Manufacturing

Industry 4.0 and the Internet of Things (IoT) are changing the PCB Assembly handle through mechanization, information analytics, and machine learning. Keen manufacturing plants prepared with real-time checking and prescient upkeep capabilities are moving forward generation productivity, diminishing downtime, and improving item quality.

4. Natural Sustainability

Sustainability is getting to be a key thought in PCB gathering fabricating. Companies are receiving eco-friendly hones, such as decreasing squander, utilizing renewable vitality, and planning items for recyclability. The move towards lead-free patching and other naturally inviting materials will proceed to shape the industry in the coming years.

Conclusion

Surface Mount Technology (SMT) has revolutionized the gadgets industry by empowering littler, more proficient, and cost-effective PCB plans. SMT Circuit Board, Surface Mount PCBs, and SMT PCB Sheets are at the heart of incalculable electronic gadgets, from customer hardware to restorative hardware and aviation frameworks. The fabricating prepare of these sheets, counting plan, Assembly, and testing, is exceedingly mechanized and exact, guaranteeing the generation of dependable and high-performance PCBs.

As innovation proceeds to advance, producers must adjust to unused challenges and openings, such as component miniaturization, progressed materials, and natural maintainability. The future of SMT PCB Assembly fabricating looks promising, with advancements in savvy fabricating, progressed bundling, and maintainability forming the another era of electronic devices.

Understanding the complexities of SMT PCB Assembly fabricating is fundamental for anybody included in gadgets plan or generation, as it remains a basic perspective of advanced innovation advancement.